Expert Wiring Harness Factory

with 20 Years Experience

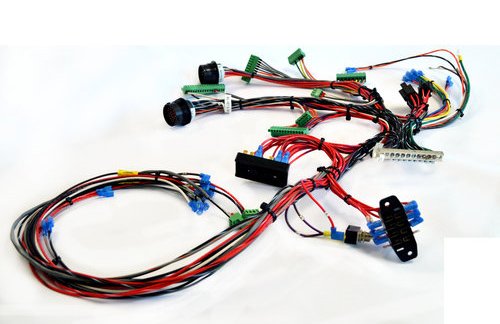

One-stop source for your wiring harness & cable assembly project

Custom Cable Assembly Manufacturer

Provide a full range of wire & cable customization services, fully meet the needs of

various industries

Your Expert Wire and Cable Harness Manufacturer

- Since the year 2000 with a good reputation

- All raw material is ROHS & REACH & HF compliant, tested by SGS

- Factory ISO certified

- Custom wire harness assemblies are built per your specific needs

- 20 years of import experience makes overseas raw material lead time fast

- High-performance wire materials, PVC, SR-PVC, TFE, PTFE, PU, XLPE, etc.

All Types of Cable & Wire Harnessto

to Support Your Project and Business

As a leading custom manufacturer of cable and harness assemblies in China, QLCable Electronic brings over 20 years of experience to wiring harness production.

We design and manufacture all types of wiring harnesses tailored to your specific requirements. Using cutting-edge technology and equipment, we deliver cost-effective, high-quality solutions.

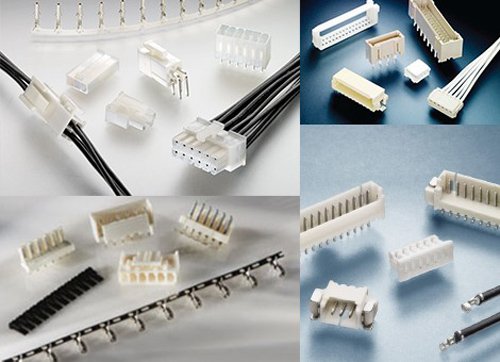

If you're looking for competitive quotes with original connectors, we can provide them—featuring brands like MOLEX, TYCO, JAE, JAM, Aptiv, YEONHO, JST, DUPONT, HIROSE, Amphenol, and more. We can also suggest alternative connectors to help you reduce costs.

Wiring Harness Categories

Wiring Harness Factory Support Your Projects

No matter what type of electrical cable assembly your project requires, QLCable Electronic is equipped to meet your needs.

As an experienced custom wiring harness manufacturer, we understand the specific requirements of your wire harness and cable assembly applications. By considering every detail, QLCable Electronic can help you design custom cable harness solutions that perfectly support your projects.

Why QLCable.com is Trusted by Numerous Clients

Over 1000 Clients Globally

Over 20 Years Custom Made Wiring Harness Manufacturing Experience

With over 20 years of experience in wire harness kits and cable assembly manufacturing, QLCable Electronic offers a wide range of OEM harness solutions tailored to your project needs.

UL Certification

QLCable Electronic operates under a comprehensive quality management system. All of our wire harness cables and raw materials are UL-certified, ensuring the highest standards of safety and quality.

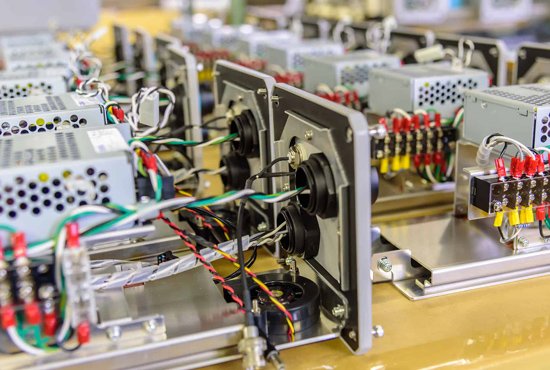

Automatic Wire Harness Production Line

QLCable Electronic features an advanced wire harness assembly production line. Our automated systems enable high productivity, with a capacity of up to 1,000,000 units.

ROHS & REACH & HF, SGS

Our wire loom harness materials are ROHS, REACH, and HF compliant, and have been tested and certified by SGS.

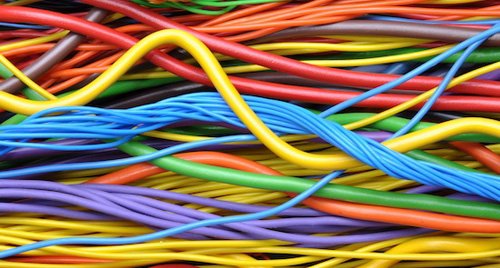

A Variety of Wire Types

We use high-performance wire materials such as PVC, SR-PVC, TFE, PTFE, PU, and XLPE to meet the demands of unique applications.

Original & Alternative Connector

We use original connectors from brands like Tyco, Delphi, AMP, Molex, JST, and JAE. Additionally, we can recommend alternative connectors and wires to help you reduce costs without compromising quality.

Who Use QLCable.com Wiring Harnesses

QLCable Electronic Ltd Wiring Activity

Wire Harness Production Line

Wire Harness Exhibition

Wire Harness Warehouse

Send us Your Inquiry

FAQs

How to make up a wire harness/cable assembly?

Wire harness assembly plays a critical role in nearly all electrical applications, which is why global demand for these components continues to rise. However, the manufacturing process is not widely understood. This guide will provide key insights to help you better understand each step involved in the cable and wire harness manufacturing process.

Step 1: Coming up with the Best Design

Regardless of where a wire harness is installed, its primary functions are to ensure a continuous, efficient flow of power and the uniform transmission of information. However, proper research and development are essential to achieving this in electronic products. The design must incorporate the necessary components and specifications to address everyday electrical challenges before implementation.

The most challenging aspect of design is ensuring a well-defined custom approach to cable assembly for maximum efficiency. This process also involves creating a precise blueprint that will guide production from start to finish.

Step 2: Creation of a Prototype

Creating a cable harness assembly prototype allows the manufacturer to gain a clearer understanding of the final product. During this stage, the prototype undergoes thorough evaluation and testing based on its intended applications. Once the prototype passes these assessments, the production phase begins. This step is crucial in ensuring the final product delivers optimal performance.

Step3: Manufacturing and Assembling

This step involves executing the design specifications developed in the earlier stages. It is crucial to maintain strict quality control measures, aiming for zero or minimal errors. While automation plays a key role in this phase, it's important to recognize that custom wire harness production still relies heavily on manual assembly, despite the advancements in technology that have impacted manufacturing globally.

Incorporating automation into the cable assembly process is a beneficial option, given the complexity of the fabrication steps. However, due to various production factors, handmade wire harness assembly remains the preferred choice, even in today's era. This is largely because of the intricate and time-consuming procedures required to complete the manufacturing process.

Manual application during wire harness assembly therefore includes:

- Applying tape in different locations and in different amounts

- Crimping the terminals to the wires, which will at times require several crimping procedures

- Inserting the sleeves into each other

- Tightening the clamps and strands, and cable ties.

Another key reason for manual production in custom cable assembly is the need for precise customization. Each wire harness must be specifically tailored to its intended application.

Custom cable assemblies are designed to address challenges in various manufacturing processes, providing both geometric and electrical solutions. Geometrically, they are crafted to fit seamlessly within a larger electrical wiring and component network.

Therefore, production must ensure that the custom cable assembly offers the necessary protection during use. This includes guarding against internal and external damage caused by moisture, crossed wires, and exposure to chemicals.

The production step will therefore include:

1.Wire Cutting

The wires must be precisely cut to the specified lengths to create an efficient and properly designed custom wire harness. This process is carried out using a wire cutting machine.

2. Stripping

Stripping is a crucial step that follows wire cutting. It involves removing the insulation from the wire ends to expose the cores, allowing for the attachment of connector housings or terminals.

3. Assembly

Finally, the wires will then be placed into the harness through a workbench or the assembly board. This is to ensure they meet all the design specs.

4.Testing the End Product

After production is completed, all wire harnesses undergo electrical safety testing. This process simulates real-world conditions to ensure the cable assembly meets all required specifications. This final step is crucial for verifying that the product will deliver 100% reliability in its application, regardless of the environment.

Finally,

Wire harness production is a complex process that requires a deep understanding. From design and assembly to the final cable assembly product, each step must be carefully executed.

Each custom cable assembly is designed to fulfill a specific purpose and integrate seamlessly with its application system, making wire assemblies essential in today’s world.

How to choose a wire type for the wire harness/cable assembly?

Designing even the simplest cable assembly involves several factors, with wire and harness selection being one of the most critical. The type of cable wire used directly impacts the effectiveness of the wire harness in its application. Therefore, choosing the right wire is a crucial component in the design of a cable assembly.

The choice of cable assembly wire can significantly impact the functionality, safety, and efficiency of the assembly. However, selecting the right wire type is often challenging due to the wide range of available options. This guide aims to address common questions and provide insights into the process of selecting the appropriate cable assembly wire.

What should I consider in terms of wire size?

There are two key factors in selecting the size of a custom cable assembly wire: length and gauge. When it comes to gauge, considerations like load and current capacity play a significant role in wire selection, with these factors measured in amps. It's important to note that wire gauge is inversely proportional to the number of amps that can safely flow through the wire harness.

Wire length is another important factor. Since no wire is a perfect conductor, longer wires increase the likelihood of voltage loss. This, in turn, raises the amperage, ensuring that the proper amount of electricity is distributed through the system.

How flexible the wire has to be?

Numerous wire assembly types feature various flexibility degrees as outlined below:

Solid core wires: these wires offer minimal flexibility in lower gauges but tend to become more flexible as the gauge increases.

Stranded coarse wires: these wires are more flexible, allowing them to maintain a specific shape while offering greater adaptability.

Fine stranded wires: these wires are highly flexible but lack the ability to maintain a fixed shape.

What wire is the best for insulation cable assemblies?

With wire insulation, the wire harness working area will have a significant impact in terms of voltage, coating, and abrasion resistance, among other factors, as indicated below:

- Voltage: The voltage level influences wire selection, as higher voltage requires thicker insulation. This helps to effectively minimize the risks of shocks and shorts.

- Coating: A coated wire simplifies the assembly’s connection.

- Environmental consideration: harsh environmental conditions, including temperature, UV lights, and chemical presence, can impact the performance of a wire within a cable assembly.

- Regulations and requirements. The requirements and rules governing the wire harness production will have a huge impact on the choice of wire.

Does the wire color have significant importance to the assembly?

Colored wires in an electrical harness are important for both users and those servicing the wire harness. It's essential to understand the purpose of the cable assembly wire before making a selection. Manufacturers use different wire colors in a cable assembly to help users easily identify neutral and ground wires, simplifying the process of installation and maintenance.

Which wire serves better in a cable assembly between copper and aluminum wires?

Copper is often the best choice due to its excellent conductivity, but it can be costly for some. For long-distance wire harness applications, aluminum wires are a more affordable option. While not as conductive as copper, aluminum wires with thicker gauges are still effective conductors. Ultimately, the choice of material depends on the specific requirements of the wire harness application.

Finally

In summary, the type of wire used in your cable assembly will depend on the specific industrial application of your project. For automotive cable assembly applications, it's important to choose a wire that can withstand harsh environments.

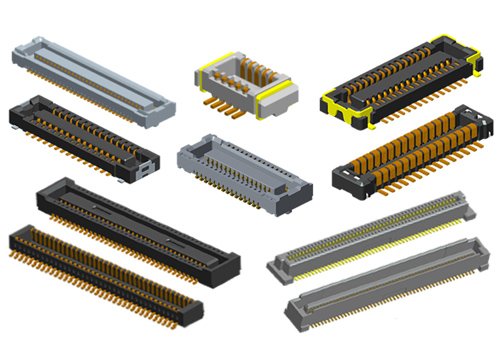

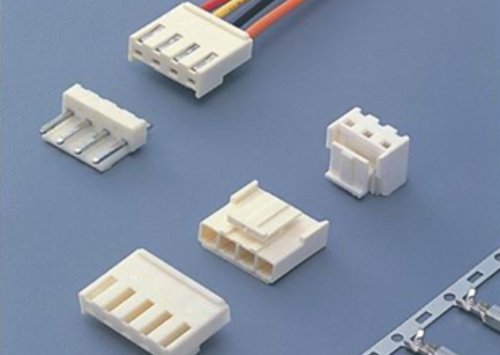

What is a connector? What are the different types of a connector?

To maximize the effectiveness of a cable assembly system, selecting the right connector is crucial. The proper connector ensures that the cabling system performs optimally within its intended environment. So, what exactly is a connector? Read on to learn more.

A connector is a component attached to the end of a cable, allowing it to easily plug into an electrical system or socket. Connectors come in two types: male and female. Male connectors typically have one or more exposed pins, while female connectors have corresponding holes designed to receive these pins for a secure connection.

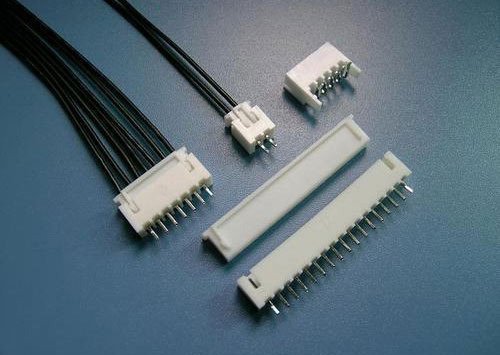

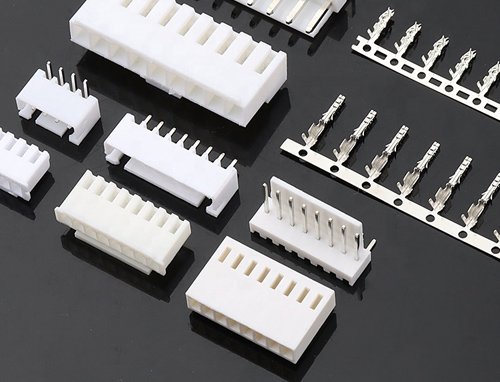

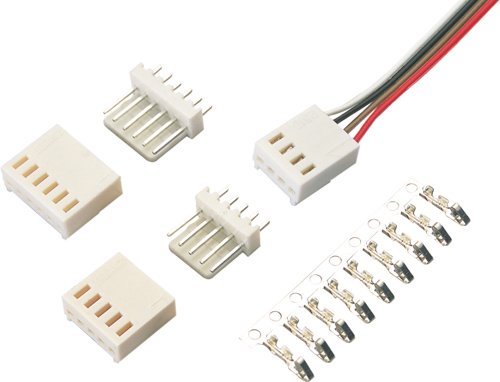

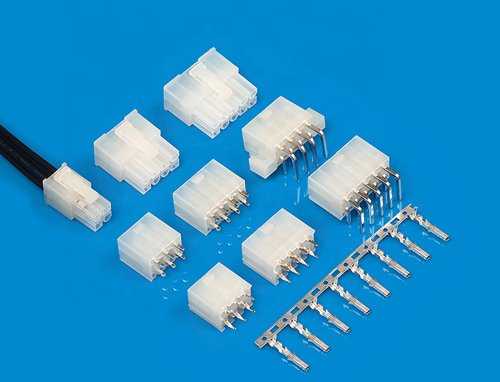

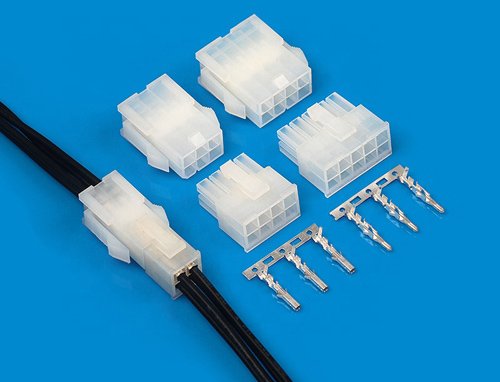

With this in mind here are some of the most commonly used connectors for cable assemblies:

- Board to board connector

- Wire to board connector

- wire to wire cable connector

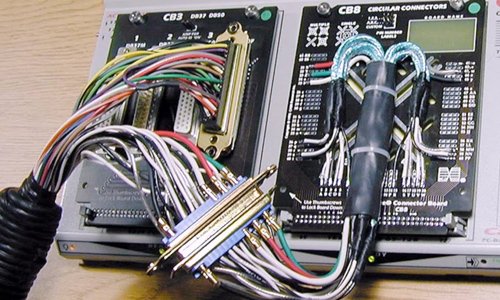

Board-to-board cable connectors

Board-to-board connectors are used to connect PCBs directly without the need for cables. These connectors are crucial for saving space, making them ideal for systems with limited room. PCBs can be connected using these connectors in either a vertical or parallel configuration.

Connectors designed to join two PCBs through a stacking arrangement are known as mezzanine connectors. However, this term is sometimes also used to describe perpendicular PCB arrangements, such as those found in motherboard-daughterboard configurations, where the emphasis is typically on parallel connections.

When selecting a mezzanine connector, several aspects and specifications need to be considered. These include mechanical requirements such as stack height, tolerance, and limitations like brackets and standoffs. For separability, it's important to determine whether the connector is intended to be permanent or detachable and to consider the total number of mating cycles the connector must endure over its lifetime, among other factors.

Some of the common examples of Board board cable connectors include:

- LEL Board-to-board connector: this board-to-board connector features a 1,2mm mating height which makes it possible for the connectors to provide important features within a cable assembly such as space-saving options and simple connections between a PC boar. It also has a mechanism that helps in the prevention of wrong insertions.

- DID board-to-board connector feature a 2.54mm pitch. It was originally designed for TV applications. This connector has a secure locking system that helps in holding the house and improves the PC board resistance to vibrations and shocks

Wire-to-board cable connectors

A Wire to board connector is used in connecting wire/cable to the PCB. It has a similar connection to that of a wire-to-wire connection. The board connection is mostly soldered two-piece or press-in connectors. However, card edge types are still being used. While these connectors have lots of applications, they are mostly used in cable assemblies to maximize the advantage of IDC benefits.

Examples of wire-to-board cable connectors include:

- RAD connector: this is a hybrid wire to board connector that is perfect for automobile radio applications.

- JWPF connector: this connector is mainly designed for smaller applications that require water ingress resistance.

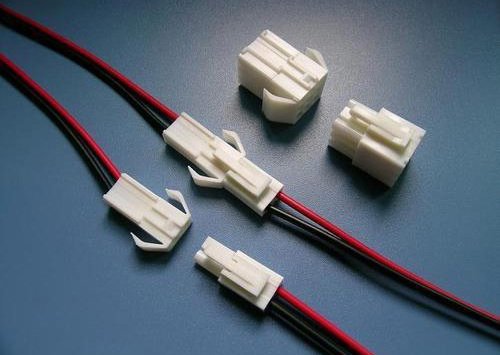

Wire-to-wire cable connectors

Wire-to-wire connectors as the name indicates are used in connecting two wires. One of the connectors will be permanently connected to a wire while the other part of the connector forms separable interfaces. To achieve the permanent connection you either apply crimping or insulation displacement contacts.

With IDC, the connection is achieved through the insertion of insulated wires into the sharpened metal beam’s slot. The edges of a beam will cut through the insulation thus making a rigid contact within the two components which is the wire and beam.

In cases where discrete wire assembly is required, the crimping process is used. However, for multi-conductor cable termination, IDC is the preferred method due to its numerous advantages in wire mass termination and handling.

Wire-to-wire connector features a wider option when it comes to housing geometrics. This includes circular and rectangular housing made from different polymer varieties and metal shells majorly for military uses.

Some of the examples of wire-to wire connectors include:

- PicoBlade connector; Offers a balance between size, performance and affordability.

- Micro-Fit Connector: Features premium housing specifications that help in reducing terminal back-outs and operator fatigue during the assembly.

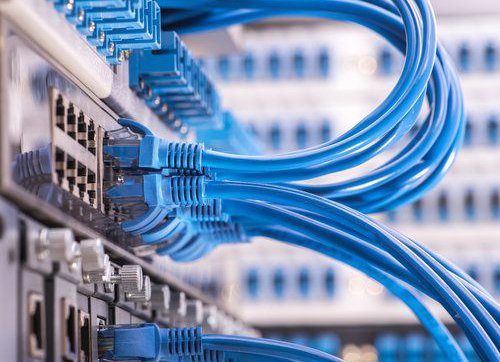

Twisted-Pair Cable connector

This connector is primarily used with both unshielded and shielded twisted pair cables. Its design includes a modular jack and plug with an asymmetric shape, allowing it to be keyed. This means that a twisted pair connector has a specific pin configuration for proper alignment and connection.

Both types of twisted pair cable connectors can be used with IDC connectors for connecting patch panels and wall plates. However, unlike screw-down connections, the cables do not need to be stripped for termination. Instead, the connectors are pressed against piercing blades that penetrate the plastic insulation to create contact.

Finally

Each connector type plays a crucial role in its specific application. Therefore, it is essential to thoroughly understand your application requirements before selecting a cable connector. This will help you decide whether to opt for a custom connector or an industry-standard connector.

How to choose a connector for wire harness/cable assembly?

Connectors play a crucial role in electrical applications, but selecting the right connector for your wire assembly is key to ensuring maximum efficiency. While this may seem like a simple task, the reality is that without proper guidelines, the risk of choosing the wrong connector is high.

With over a million connectors available, here are five key questions to consider before deciding which cable assembly connector to use.

What is the electrical requirement for the connector?

A good starting point for narrowing down your connector options is to consider the electrical requirements. This includes the voltage, number of signals, currents, and the frequency being transmitted. The signals can be power, digital, analog, or a combination of all three. Additionally, both analog and digital signals can operate at either low or high frequencies. The specific combination of these signals will directly impact the type of connector, pin-out, and wire assembly needed.

Also, keep in mind that other signal combinations might not be compatible with the same wire harness connector inclusion. If you are therefore dealing with electrical signals only or surgical equipment that requires gas or fluid lines, then a custom connector will be perfect for your cable assembly.

Are size and space a constraint?

New technological trends emphasize size reduction across nearly all sectors of electric machinery. Machines that once took up significant space have been transformed into portable devices. This shift impacts the size, weight, and space available for connectors, leading to a demand for connectors that can endure higher mating and unmating frequencies.

If this is the case with your project, you have to make sure you go for a wire harness connector that can match your project application.

Will the connector operate under extreme environments?

Most wire assembly connector systems are designed to withstand extreme industrial and mechanical conditions, including shocks and vibrations. Connectors intended for these environments typically feature specialized elements such as threaded coupling and strain relief. Threaded coupling prevents the connector from vibrating loose, while strain relief supports and stabilizes the connector wire harness.

Such connectors usually indicate their specification. This means you can easily tell if the selected connector can withstand harsh environments.

Are there any obligatory industry requirements?

Most industries have established standards that OEMs must adhere to. While these requirements may impact the connectors themselves, they generally apply to the machinery the connectors are part of. For instance, the FDA sets standards for medical equipment, SAE oversees automotive standards, especially for hybrid vehicles, and MIL standards are applied to defense-related machinery.

These standards are not only limited to covering reliability and performance but even the manufacturing standards and stringent qualifications. Therefore, make sure you abide by all the necessary standards within your industry.

What type of termination is required?

Terminations are crucial for connecting a socket or wire-to-wire connector pin to a conductor, which can be a PCB, wire, or other components. It’s important to consider the available terminal types: crimped connections, press-fit, wire wrap, or soldered connections. Each type of termination has its own unique features and advantages.

Finally

Each custom connector application has its own unique requirements, design constraints, and cost considerations. Therefore, use the questions outlined above as a guideline to help narrow down your options effectively.

What is the difference between original and alternate /replacement /equivalent cross connector?

Connectors are devices used to join or complete electrical circuits and signals. They can be either temporary or removable, though some are designed to be permanent. The main purpose of connectors is to make electrical products easier to assemble and manufacture, while also ensuring efficient signal and current transmission.

They are also responsible for easing circuit repairs and allowing resilience in modification and design. They are mainly used on circuits for industrial machines, communications, PCs, and consumer electronics.

Well, there are different types of connectors, all based on their applications. However, in this piece, we will be outlining the significant differences between an original connector and an equivalent connector, also known as replacement connectors.

So what is an original connector?

Original connectors refer to those produced by well-known and established manufacturers such as Molex, JAE, JST, Lumberg, and TE. These companies have a long history in the industry and are renowned for their high-quality connector production and ongoing innovation.

What is an equivalent connector?

An equivalent connector, also known as a replacement or compatible connector, is typically produced by local manufacturers. However, this does not imply that these connectors are of inferior quality. In fact, their specifications, such as pitch, appearance, temperature range, and material, are often comparable to or even exceed those of original connectors.

The main difference lies with the fact that a locally manufactured cross connector does not have that famous tag that comes with an original connector. However, they also can become original connectors in the future.

Why is an equivalent connector the most preferred choice by many users?

Although a Chinese equivalent connector might not always match the high standards of an original connector, they are still a popular choice for many users due to their cost-effectiveness. The lower price is a significant factor in their widespread preference.

Many people, therefore, prefer an alternate connector due to the following reasons:

- These connectors come at an affordable price

- Customized according to your specifications

- Features regular updates

- Quick delivery

End users do not have to use the producers brand

Increases design flexibility

- Easy to use

The major setback with an alternate connector is its low lifespan.

Cross connectors application includes in small home appliances such as electric fans, electric iron, and kettle, just to mention a few.

Some of the local manufacturers of alternate connectors in China include ECOCABLES, LHE, JVT, HR, and HRB.

Important to note is that some equivalent connector quality can be better than original connectors depending on the production process and the skills put in place.

Why use original connectors?

Original connectors are often preferred because many people trust the products of well-established, reputable companies. These connectors are known for their high-quality production, achieved through advanced technology and precision machinery, which sets them apart.

Original connectors, therefore, stand out due to the following reasons:

- Longer life span of up to 10 years

- Larger markets, including overseas markets

- High-quality products

- Ability to thrive even in harsh environment

- Minimal power loss

The main disadvantage of original connectors lies with their price. These connectors are mostly expensive.

Original connector is primarily used in the application of home appliances, medical equipment, smartphones, camera, elevators, and mostly in office machines, including computers.

Finally

The choice between original and equivalent connectors largely depends on the user's preferences and the specific requirements of the project. Both types of connectors can provide exceptional performance, so the decision ultimately comes down to what best suits your needs and project goals.

However, it is crucial to consider factors like delivery time, required certifications, quality, and your project's budget before making a decision. Keeping these aspects in mind will help you make an informed choice between equivalent or original connectors.

How to check if a harness/cable assembly is good or not?

A wire harness cable assembly is essential for commercial, consumer, and industrial products, providing reliable power sources for various applications, from power tools to high-demand systems like security installations. Despite rigorous mechanisms to identify and correct errors during production, a small percentage of issues might still go unnoticed. Therefore, testing these components before use is crucial. The testing process helps detect any errors and ensures that all assembled components are functioning correctly.

To minimize the risk of errors in your cable assembly during application, it is advisable to conduct several assessments. These tests should evaluate the mechanical, electrical, environmental, and signal integrity aspects of the harness. To help you ensure your wire harness is in optimal condition, this guide will detail the essential tests to perform.

Mechanical Tests

Mechanical tests assess the mechanical characteristics of the wire harness to ensure it meets the requirements of its intended task. These tests help identify issues related to the harness’s flexibility, elongation, tensile strength, and resistance to crush and impact. By conducting mechanical testing, you can effectively evaluate and address potential errors in the cable assembly.

While mechanical testing can reveal many errors, intermittent issues can be more challenging to detect because they do not occur consistently. These errors may only manifest under specific conditions, such as particular positions or temperatures. Some common causes of intermittent errors include:

- Badly placed specifications: this is where a value is set to only allow the cable to pass the intermittent assessment. However, readjusting different specification values will help in eliminating this error.Badly placed specifications: this is where a value is set to only allow the cable to pass the intermittent assessment. However, readjusting different specification values will help in eliminating this error.

- Cold solder joints: Moving a contact before the solder is set will make the solder weak, leading to intermittent errors.

- Damaged housing/ insulation: damaged wires from the connector’s housing will cause intermittent shorts.

- Dirty contacts: contacts that have dirty residues or other contaminations can lead to intermittent errors.

- Bad interface; Worn out cable interfaces of contacts will make it almost impossible to identify intermittent errors with the harness.

Environmental Tests

Environmental tests assess whether the wire harness can perform effectively in various conditions. To endure harsh environments, such as high temperatures and humidity, the harness must possess the appropriate capabilities and features, with no errors. Wire harnesses that function optimally under specific environmental conditions are deemed the most suitable for your application.

Visual Tests

Visual assessment involves identifying errors that are visible to the naked eye. During a practical visual inspection, ensure that all harness components are properly fitted and in good condition. Key aspects to check include:

The cables/wires gauge and placement. You should also check for any damage to these wires.

The terminals/ connectors. Here you have to ensure the appropriate connector types or terminals have been used in the custom wire harness.

- The labeling. Proper labeling helps when it comes to placement and accuracy.

Performing a test on the harness dimension also plays a vital role in determining if your cable assembly has met the right specifications.

Signal Integrity Tests

Signal integrity testing examines various errors in the wire harness, with a primary focus on signal strength. It also detects standard issues such as crosstalk malfunctions. This assessment helps determine if integrating components like filters and splices can maintain or enhance the signal strength of your cable assembly.

Final Thoughts

Remember, passing production testing does not guarantee that the cable is flawless. Manufacturers might still overlook issues. Conducting the tests mentioned above ensures that you can confirm with certainty that your cable assembly is completely reliable and error-free.

How to reduce wire harness or cable assembly cost?

wiring harness loom plays a crucial role in many applications, but designing and manufacturing it can be more costly than expected. Custom wire harness production can significantly impact your budget. While maintaining quality is essential, there are several strategies you can employ to reduce costs without compromising on performance. This piece outlines practical approaches to help you save money in the production process.

Before exploring cost-saving options for your wiring harness loom, it's crucial to review two key aspects. Ensuring that you adhere to the regulations governing affordable wire harness manufacturing is essential, even as you seek to reduce costs.

Bill of material catalog: This is a list that highlights all the materials required to produce a cable loom. Taking a look at the list can be an excellent place to start your venture as far as cost-saving cable assembly is concerned. However, you must also ensure that you abide by the CMs rules and regulations. Also, pls ensure you follow OEM material rules.

- Specifications catalog: This catalog will help you have an easy time inspecting all the materials and components of your custom wiring loom. It will also help you identify areas where you offer cost-saving options. This must, however, be done by putting into consideration the quality of your wiring looms and harnesses.

Having a clear understanding of these two catalogs or documents will help you have an easy time considering these cable assembly cost-saving options.

Go for the suitable materials

Raw materials play a crucial role in the manufacture of cable assemblies. To save costs, it's advisable to order materials in bulk. However, this should be done only after carefully selecting the appropriate combination of raw materials.

Pick the right connectors

Cable assembly production involves various types of connectors, and the method used to integrate these connectors—whether soldering or crimping—can significantly impact production costs. By understanding the specific transmission requirements of your cable assembly, you can choose the most suitable connectors and methods, ultimately leading to cost savings.

The cable conductors

The general rule is that smaller conductors are less expensive. However, it's important to ensure that reducing conductor size does not compromise the future performance or functionality of your wire harness.

Make sure you go for an affordable conductor that has the ability to meet your assembly’s requirements.

Go for cost-saving wire options

Many manufacturers spend excessively on expensive wires that aren't necessary for the wire harness assembly. To optimize costs, first ensure that the wire you select meets the required certifications for your specific application. Once you've verified that the wire is compliant, you can more effectively choose cost-efficient options.

Settle on proper testing

For cable assemblies with extensive applications or heavy workloads, thorough testing is crucial. Relying solely on partial or visual tests may not be sufficient. Conducting comprehensive tests helps identify potential issues that could arise later, thereby reducing the risk of costly repairs and replacements in the future.

Go for experience

When selecting a manufacturer for your cable assembly production, choosing one with substantial experience is crucial. An experienced manufacturer can provide reliable guidance on materials, which is key to cost savings. They can help identify affordable yet dependable material alternatives.

A skilled team that works cohesively is essential for achieving your goals. A manufacturer who understands your organization's specific needs will be better equipped to advise against unnecessary materials. Therefore, partnering with a knowledgeable custom cable assembly manufacturer ensures both time and cost efficiency.

Finally

There are several strategies to reduce costs during custom wire harness production. However, it’s crucial that these cost-saving measures do not compromise the efficiency of the wire harness. Cutting corners could lead to issues down the line, ultimately resulting in higher costs.