Home Appliance Wiring Harness Manufacturer

Alternator Wiring Harness

An alternator features a wiring system that facilitates energy transmission within a machine, encompassing battery recharging and powering various electrical components.

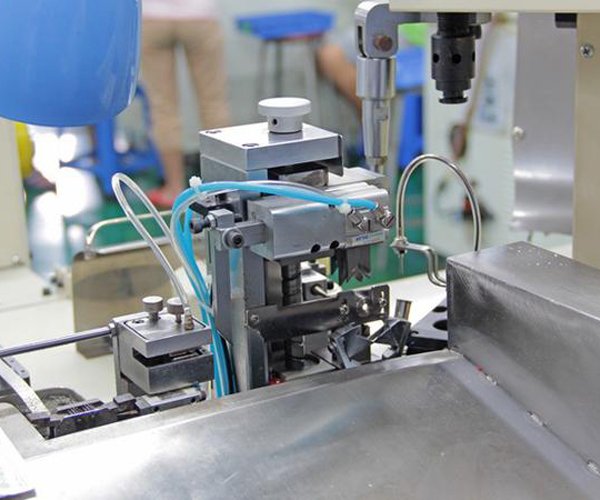

The alternator cables require bundling into a single harness for protection and orderly arrangement.

The process of binding the alternator wiring system is known as an alternator wiring harness. It involves incorporating an additional insulator or sleeve to keep the cables united. The terminals of the wire harness ensure that the cables are connected with connectors that attach to the necessary components.

- UL / VDE cable

- Customized length

- OEM ODM accept

- Wire Gauge: AV 0.254/16 OD2.45 18AWG

- Wire Length: 160mm or Customized

- Model Number: 4-pin female plug connector SJ-83370

- Certification: ISO9001, IATF16949

Alternator Wiring Harness

If you own a car, you likely have a basic understanding of an alternator. Essentially, an alternator is a crucial component of a car's engine. An alternator generates an electric current used to power automobiles and recharge their batteries.

You may be curious about how an alternator accomplishes this. The alternator is designed to convert mechanical energy into electrical energy by transforming AC into DC. It supplies electricity to automotive electrical components such as fans, windshield wipers, and lights. Therefore, alternators require small wiring harnesses. The alternator wire harness safeguards the cables that transmit energy from the alternators to the car's components.

Features of Alternator Wire Harness

The alternator harness comprises of well-organized cable connected to an alternator.

- Copper Conductor - The cables feature copper conductors that are utilized to transmit power energy from the alternator to other automotive components. Copper conductors are favored due to their high conductivity and low resistance properties.

- Insulation - PVC insulation covers the cables. This insulation ensures that the conductors in different wires do not come into contact with each other, preventing electrical shorts.

- Wire Harness - The cables are bundled together to form a single assembly of wires. The wire harness provides adequate protection for the individual cables against harsh environmental conditions.

Advantages of Alternator Wiring Harness

Alternator wire harness comes with significant benefits that unassembled wires can’t offer.

- The Alternator Wire Harness organizes the wires that carry electricity from the alternator to other car components. Consequently, it makes it easy to identify specific cables with the assistance of the wire harness.

- It protects the wires from abrasion that may be caused by intense vibrations. Such abrasions can occur when wires rub against each other, leading to the exposure of the electrical conductors.

- It ensures easy installation and replacement of burnt or damaged cables. The wire harness simplifies the installation process and reduces the time required, as you only need to disconnect the entire wire harness and install a new one.

- It creates space for other components within the car's engine area to operate efficiently. It minimizes the confusion that can arise from unorganized wires.

- The robust insulation ensures that the alternator harnesses are efficient, durable, and reliable. The rubber material safeguards the cables from corrosion caused by engine fluids, oil, moisture, and other chemicals.