Industrial Wiring Harness Manufacturer

Fuel Pump Wiring Harness

A wiring harness for a fuel pump has been designed to safeguard the numerous wires within it. This approach facilitates the bundling of wires into a single harness.

The cabling and wiring inside the pump are unlikely to be exposed to risks such as fire, abrasion, or corrosion, presumably due to vibrations.

- Wire harness maintains fuel pump wires’ quality and durability, promoting its application.

- Offers extra protection to wires aside from their normal insulations

- Organizes wires in an orderly manner and binds them to reduce the intensity of vibrations

- Helps to reduce the wiring system’s installation and repair time

- Delphi brings 80 + years of OE Heritage into each Delphi product, ensuring quality and fitment for each Delphi part.

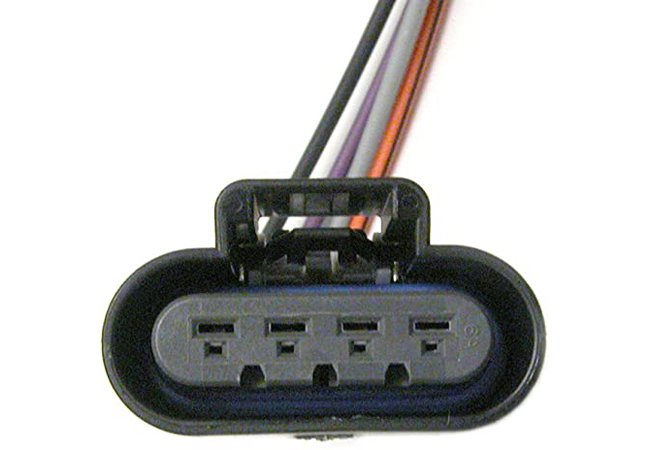

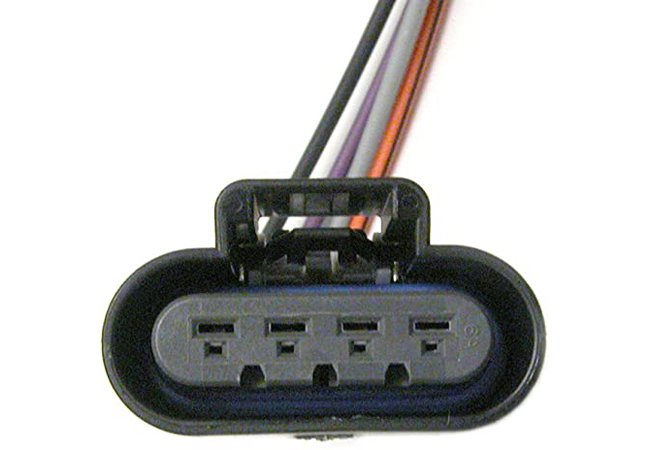

- 1 x 4 wire harness utilized on many GM applications

- Each wire harness is designed to meet or exceed the performance of the original unit

- A splice kit is included in the event the vehicle has an old, faulty connector design

- Delphi wire harnesses are designed and reliably work for the life of your fuel system

Fuel Pump Wire Harness Overview

Indeed, technology is revolutionizing the world with remarkable inventions. In the past, we relied on manual fuel pumps, but advancements in technology have eliminated the need for any effort when refueling vehicles. The electric pump accomplishes this task simply by holding the pump and pressing to dispense fuel. This invention came with various additional designs to support the fuel pump's operation.

A wiring harness for fuel pumps has been developed to safeguard the numerous wires within. This method aids in bundling the wires into a single harness. The cabling and wiring inside the pump are not susceptible to risks such as fire, abrasion, or corrosion, presumably due to vibrations. In this discussion, we will explore the features and benefits of a fuel pump wiring harness.

Characteristics of Fuel Pump Wire Harness

A fuel pump wiring harness consists of an exterior cover or sleeve that envelops the wires. This wiring harness provides adequate protection to multiple wires by eliminating any space for vibration. While the wires remain inherently bundled together, it is important to note that the wiring harness maintains the flexibility, effectiveness, and functionality of the wires.

Binding the wires together ensures their efficient power transmission, even in harsh conditions. A fuel pump wiring harness features an insulation jacket that can operate effectively at extreme temperatures and resist chemical, water, and oil corrosion and abrasion. Consequently, the conductor remains shielded from exposure, which could pose risks to the fuel pump.

Types of Fuel Pump Wiring Harness

A fuel pump wiring harness is constructed from various materials, each possessing distinct characteristics. Manufacturers select the most suitable harness material based on specific conditions to guarantee durability. Polyvinyl chloride (PVC) is commonly used due to its unique properties. PVC has a temperature range of -40°C to 105°C, but it can also operate up to 150°C. It is resistant to static electricity and abrasion, and boasts a long lifespan of 25-30 years. Other materials that may be used include vinyl, thermoplastic elastomer, and polyethylene.

Advantages of Fuel Pump Wire Harness

The fuel pump wiring harness holds significant importance due to its various benefits. The innovation of the wiring harness emerged amidst a pressing need to minimize the time and effort required to operate the fuel pump. Let's delve into the advantages of a fuel pump wiring harness:

However, it's crucial to understand that these benefits are provided by fuel pump wiring harnesses that are certified by UL and ISO 9001. Therefore, before purchasing a wiring harness, be sure to check if it holds any of these certifications.