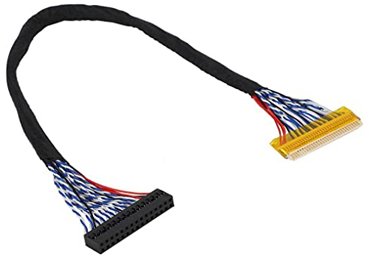

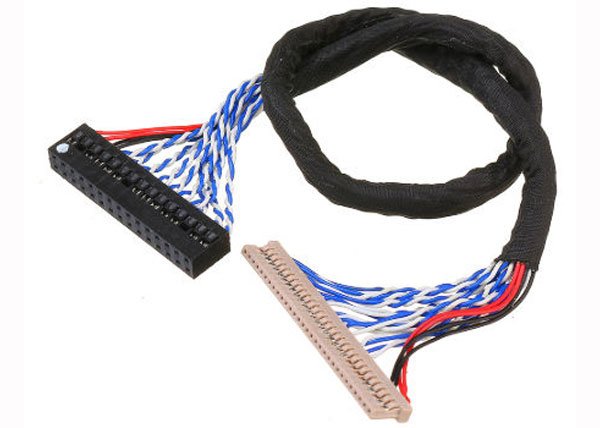

OEM&ODM LVD Cable Assemblies

LVDS cables utilize advanced high-speed technology within their circuitry to guarantee consistent multi-gigabit data transmission. Reach out to us for customization!

What Is LVDS Cable?

LVDS is a technology that underscores the significance of utilizing high-performance data transmission assemblies. Consequently, LVDS cables can be described as cabling systems capable of transferring data at extremely high speeds, albeit under twisted cable assemblies.

It is imperative for LVDS cable assemblies to comply with the 1000-ohm differential impedance requirement for LVDS signals. As such, LVDS cables have gained traction in current applications due to their ability to provide high data rates while consuming minimal power compared to other interfacing techniques.

LVDS Cable Applications

LVDS cable assemblies play a crucial role in data transfers, particularly in applications that demand substantial data transfer with controlled or low power consumption, such as PC applications. Prior to the introduction of these cable assemblies, the cables in use occupied more space and offered slower or lower data transfer rates.

However, with LVDS being endorsed by the SCSI standards, they provide superior features that make them more efficient than traditional cables. Firstly, the SCSI standards enable LVDS-specific cables to seamlessly support longer cable lengths and higher data transmission rates. Additionally, LVDS cables play a vital role in video interfacing devices.

Benefits of LVDS Cables

An LVDS cable assembly has a lot of benefits apart from the fact that they have the ability to transfer data at very high speeds.

- Noise control

- Highly efficient even under low power voltage supplies

- Significant transmissions as far as signal transmission is concerned

- Easily compatible with different systems

- Supports higher signaling rates within minimal signal integrity.

- Low EMI emissions when compared to TTL and other interfaces.

- Supports the control signals of data and clock.

Advanced LVDS Cable Assembly Manufacturing

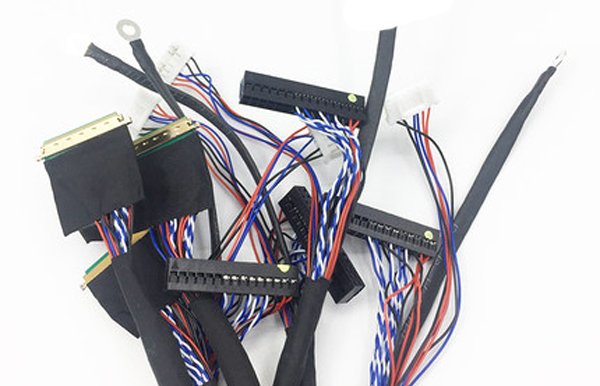

LVDS cable assemblies enjoy widespread popularity in various electronic data transfer devices, such as computers and high-definition digital TVs. Their extensive applications in network and analog video interfaces have fueled a significant demand for LVDS cables in the market.

At QLCable Electronic, we excel in manufacturing and producing high-quality, customized LVDS cable assemblies. We maintain close collaboration with our clients to ensure that every aspect of the cable assembly meets their specific requirements, regardless of the intended purpose or length. QLCable Electronic can tailor a low-voltage differential cable assembly to provide you with reliable and durable solutions.

Our team of professional engineers has designed over 10,000 high-quality, unique LVDS cables. These experts are actively involved in the entire production process of customized LVDS cable assemblies, ensuring that each customer receives a product that perfectly matches their expectations.

We are committed to delivering 100% tested, high-quality customized LVDS cable assemblies, which is why we are trusted worldwide. Trust us to help you meet your reliable customized LVDS cable assembly requirements. We will ensure that you receive the perfect solution for all your data transfer needs.

Why LVDS cable assemblies are the best option?

If you have experience working with flat screens or incorporating them into your products, you may have encountered LVDS cable assemblies.

Since their inception, LCD cable assemblies have gained widespread popularity and are now utilized across numerous sectors, including industrial vision machinery, LCD-TVs, and various communication systems. Hence, this article aims to provide comprehensive insights into LVDS cable assemblies.

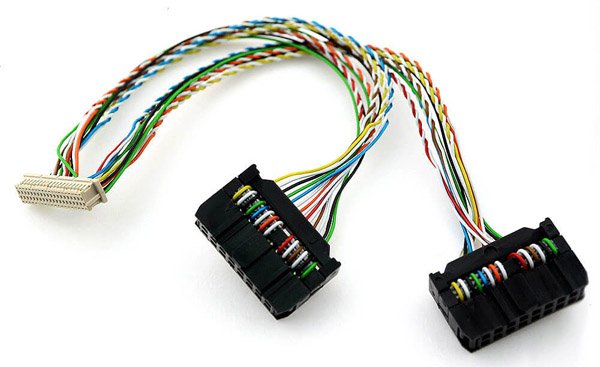

Are all LVDS cable assemblies the same?

LCD cable assemblies have gained popularity in nearly all communication equipment, encompassing smart devices and personal computers. They also excel in networking and analog video connectivity. By opting for customized LVDS cable assemblies, users can select cable lengths based on the specific needs and configuration of their LVDS system.

What are the LVDS cable problems?

- High price tags

- Twisted cables

- Features reduced jitter flexibility compared to PECL signal cables

- Cannot support data rates exceeding 3.125Gbps

Should I go for a customized LVDS cable?

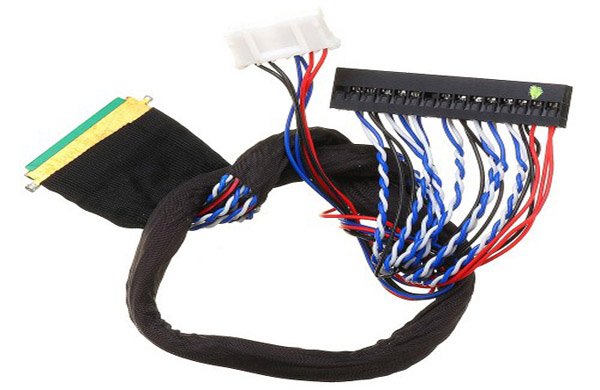

Custom LVDS cable assemblies also enable the creation of finely pitched assemblies that can accommodate even small gauge wires, resulting in a flexible cable assembly capable of rapid data transfer, even in compact units.

How to choose the right LVD cable assemblies?

Remember, LVDS cable assemblies don't necessarily need to be expensive or confusing, as long as you receive the right guidance from knowledgeable professionals who have your best interests in mind, such as QLCable Electronic. I hope this information steers you in the right direction.

How does LVDS cable assembly system work?

LVDS cable assemblies operate using a differential system approach, which involves carrying two varying electrical currents or voltages through the cables. The difference in voltage is then compared at both the transmission and receiver ends, where the LVDS encodes the data. This is facilitated by leveraging the existing difference within the wires, giving LVDS's differential data approach a significant advantage over single-ended schemes in terms of resistance to various effects, including common mode noise.

The differential transmission approach is quite distinctive. It employs two wires that exhibit opposite voltage and current swings to convey data. This is beneficial for cable assembly users because LVDS cable assemblies' differential transmission approach offers less noise interference, as the noise is coupled equally within the two cables and subsequently rejected by the receivers. This is not the case with the single-ended approach.

The receiver is designed to function by solely examining the difference between the two signals. Additionally, the receiver plays a crucial role in emitting less noise due to the cancellation of magnetic fields generated, unlike single-ended signals. At QLCable Electronic, we always strive to provide our clients with the best product, which is why our customized LVDS cables are equipped with superior features.

This includes shielding the entire LVDS cable assembly and incorporating various protective measures such as drain wires and ferrite beads. Shielding your LVDS cables not only aids in eliminating EMI but also mitigates the impact of other electronic components that could distort the overall function of the cable assembly, including the quality of the image.