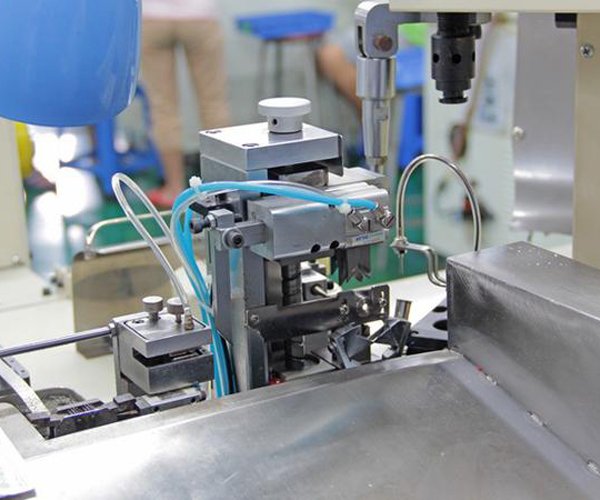

Home Appliance Wiring Harness Manufacturer

Microwave Cable Assemblies

Microwave coaxial cable assemblies are utilized in vector Network Analyzers (VNAs) and exhibit exceptional electrical and mechanical performance at frequencies reaching up to 110 GHz.

The primary function of a microwave cable assembly is to transmit signals.

- Good phase and amplitude stability

- High number of mating cycles

- High electrical and mechanical stability

- LOW MOQ 50pcs accepted

- Prototype is available, lead time: 1-3 days

- Product Name: Microwave oven wiring harness

- Impedance 50 Ω

- Frequency range DC to 110 GHz

- Mating cycles > 500

- Power handling up to 600W @ 10ghz(depends on cable and connector type)

- Compression armor 80N /mm(cable only)

Why you should choose a microwave cable assembly?

There are numerous technical factors that influence the choice of a microwave cable assembly. Ultimately, the decision hinges on the cable's electrical performance, environmental resilience, mechanical durability, and, in certain environments, its fire-resistance. These attributes are intrinsically linked to the material composition and structural design of the microwave cable assembly.

What’s the main function and features of a microwave cable assembly?

The microwave cable assembly's core function lies in signal transmission, necessitating materials and structures that ensure consistent transmission characteristics over its entire lifespan. Let's delve deeper into the key features of this cable:

1.Inner Conductor

The inner conductor of the cable is predominantly copper, existing in forms such as annealed copper tube, copper-clad aluminum wire, or annealed copper wire. Generally, copper wire comprises the inner conductor. However, larger cable assemblies often utilize copper tubes to reduce the cost and weight of the RF cable.

2.Outer Conductor

The outer conductor serves dual roles: as a circuit conductor and a shield. It also plays a crucial part in determining the leakage performance of the microwave cable assembly. The outer conductor of a microwave coaxial cable assembly must be fully enclosed to prevent radiation leakage.

3.Insulating Medium

The dielectric of microwave coaxial cables offers more than mere insulation. Its final transmission performance is largely determined after the insulation process. Therefore, careful selection of materials and cable structure is vital. Key properties like attenuation, return loss, and impedance are closely related to the insulation.

A unique multi-layer insulation coextrusion process results in a closed and uniform foaming structure, contributing to the cable's stable mechanical properties, moisture resistance, and high strength characteristics.

For enhanced electrical performance in humid environments, a customized coaxial microwave wiring harness featuring a thin, solid-core PE layer within its outer foam insulation surface can be obtained. This thin outer layer effectively guards against moisture intrusion while preserving the electrical capabilities of the microwave wiring harness.

4.Sheath

A black UV-resistant HDPE sheath aids the cable in enduring various climatic stresses caused by intense UV rays and extremely high temperatures. For fire safety, it's crucial to use halogen-free, low-smoke, flame-retardant materials. Additionally, flame-retardant and fireproof tape can be applied between the sheath and outer conductor to maintain the integrity of the easily melted insulating layer.