The cable manufacturing industry has adapted to the shifts in the modern environment, as high-quality cables are indispensable for connecting appliances and fulfilling various industrial needs across all sectors. These cables and wires are utilized in diverse applications to guarantee successful operations under varying conditions. Given the distinct applications of PVC and silicone wires, one can determine the most suitable option by recognizing their unique advantages. This article will guide you through the process of distinguishing between silicone wire and PVC wire, including the benefits each offers over the other.

What Is A PVC Wire

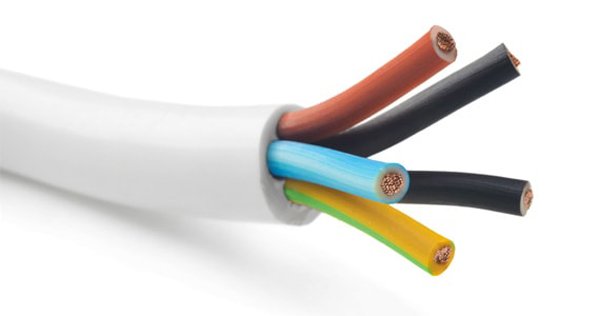

PVC wires are a widely used type of wire in electrical applications. PVC stands for Polyvinyl Chloride, a thermoplastic material that softens when heated and is produced through a process known as polymerization. PVC wires are well-known for their longevity and robust performance. Their heat resistance spans a range of -40 to 105°C, enabling them to serve for 25-30 years at a low cost. Furthermore, these wires exhibit high resistance to static electricity and foreign materials. The insulation is characterized by its rigid nature, which consequently reduces cable flexibility and maneuverability. However, it is important to note that PVC wires are relatively inflexible.

Common PVC wire Benefits

- PVC is readily available at a low cost and in various colors.

- PVC is resilient and provides longevity (25-30 years)

- PVC is resistant to weathering, chemicals, abrasion, corrosion, and impact.

- PVC is proven to be static electricity proof.

Silicone Wires

Industries have utilized silicone wires due to their broad operating temperature range, voltage characteristics, and exceptional flexibility. Silicone wire can be available as single-core or multi-core wire, making it suitable even for harsh temperature conditions. There are various gauges of silicone wires, ranging from 6-10 AWG, 12-16 AWG, 18-22 AWG, and 24-30 AWG, and they come in different colors. Depending on your project’s requirements, you can select any type and preferred color combination.

Silicone wires are a premium type of wire used in RC projects. The wire is extremely soft and flexible, making it ideal for compact and confined spaces. These types of wires are applied in various industries such as glass manufacturing, steel production, shipbuilding, aviation, and cement production. These represent the extreme environments in which silicone wires can be utilized.

Common Silicone Wire Benefits

![]()

- Silicone wires are extremely flexible.

- Have outstanding electrical characteristics

- Silicone wires are highly resistant to different types of chemicals and abrasive elements.

- Silicone wire can serve in high temperatures ranging between -50 to 2000C, but special grades can withstand temperatures up to 3000

Additionally, Silicone wires are highly applicable in aerospace. The silicone wires are advantageous over conventional wires like;

- Silicone wires are flame resistant because they ensure reduced flame propagation.

- They are halogen-free wires- Produce little smoke, thus enabling clear visuals during fires.

- Silicone wires do not produce corrosive gases.

Conclusion

Both PVC and silicone wires have distinct applications and offer varying advantages, making them unique. Therefore, the deciding factor when choosing which wire to purchase is the specific application and project requirements. To gain a comprehensive understanding of each type of wire, consider reaching out to us. We will endeavor to address your questions and assist you with your project.